How does a Porsche

air-cooled engine work?

Porsche have been synonymous with air-cooled engines from the company’s inception in 1931. The first Porsche 356, designed in 1947, ran a 1.1 litre four-cylinder air-cooled ‘boxer’ engine. This engine design followed right through to the last air-cooled 911 (the 993) which ceased production in 1998. Whilst the air-cooled boxer engine went through many different guises over the 50 years that Porsche utilised it in their sports cars the two fundamentals of being horizontally opposed and cooled by air remained.

To help break down an answer to the question above, we should first address what is a ‘boxer’ engine? As the pistons inside the engine are laid out horizontally, the combustion fires the pistons up and down the cylinder on a horizontal plane, almost looking like a boxer throwing a jab, hence ‘boxer’ engine layout. The benefit of the boxer layout for the engine is that it has a very low centre of gravity compared to an in-line or V-type engine. This assists in the handling of the car by reducing body roll. The boxer engine characteristics also provide the driver with plenty of mid-range torque meaning the engine is not needing to be high revving to produce its power, which aids reliability. The engine can also be made lighter, as fewer counter balancing weights are required within the engine because the pistons are moving towards and away from the crankshaft at the same time. A by-product of this natural balancing is the engine creates fewer vibrations. It also creates a very distinctive and pleasant soundtrack!

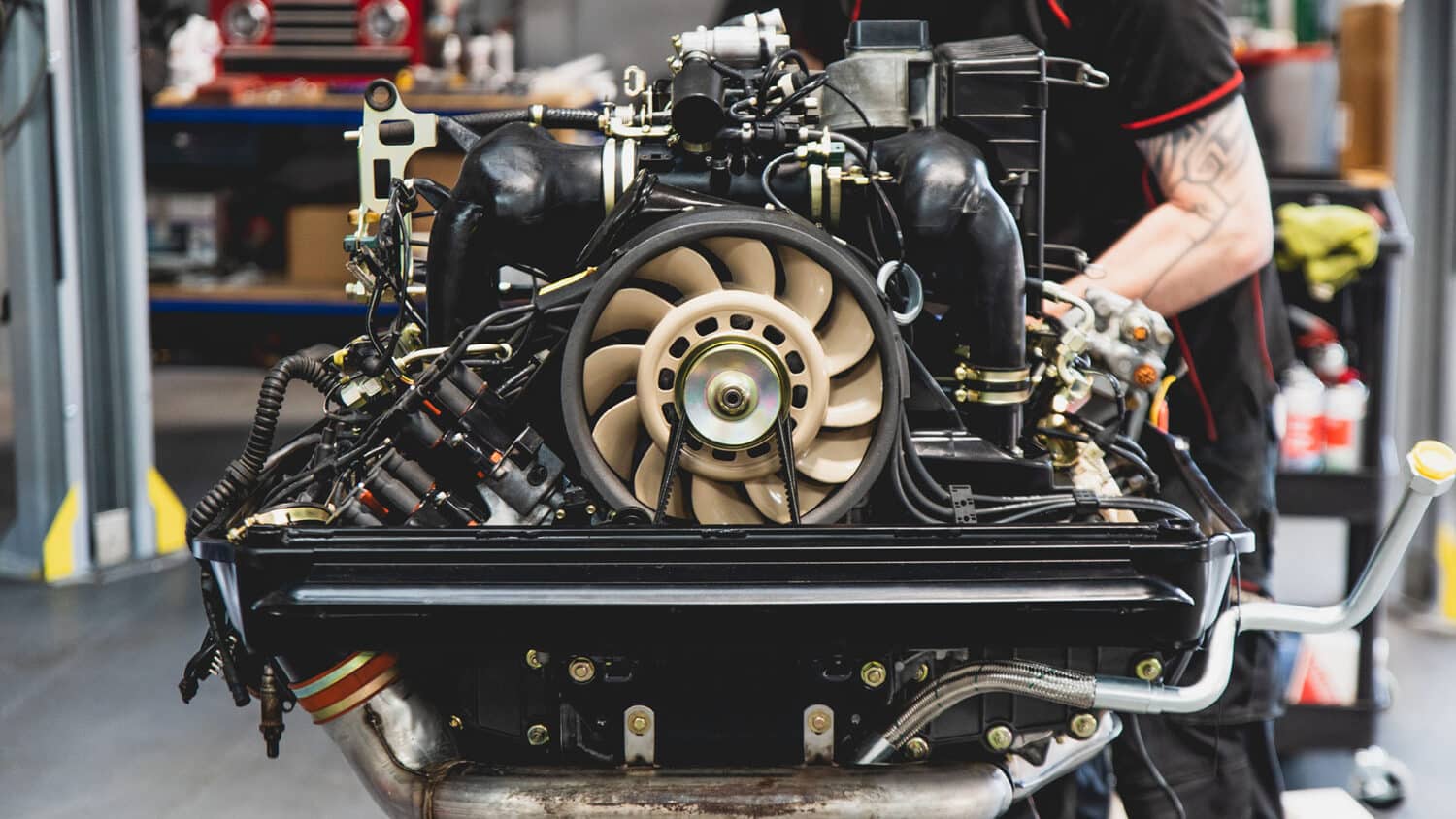

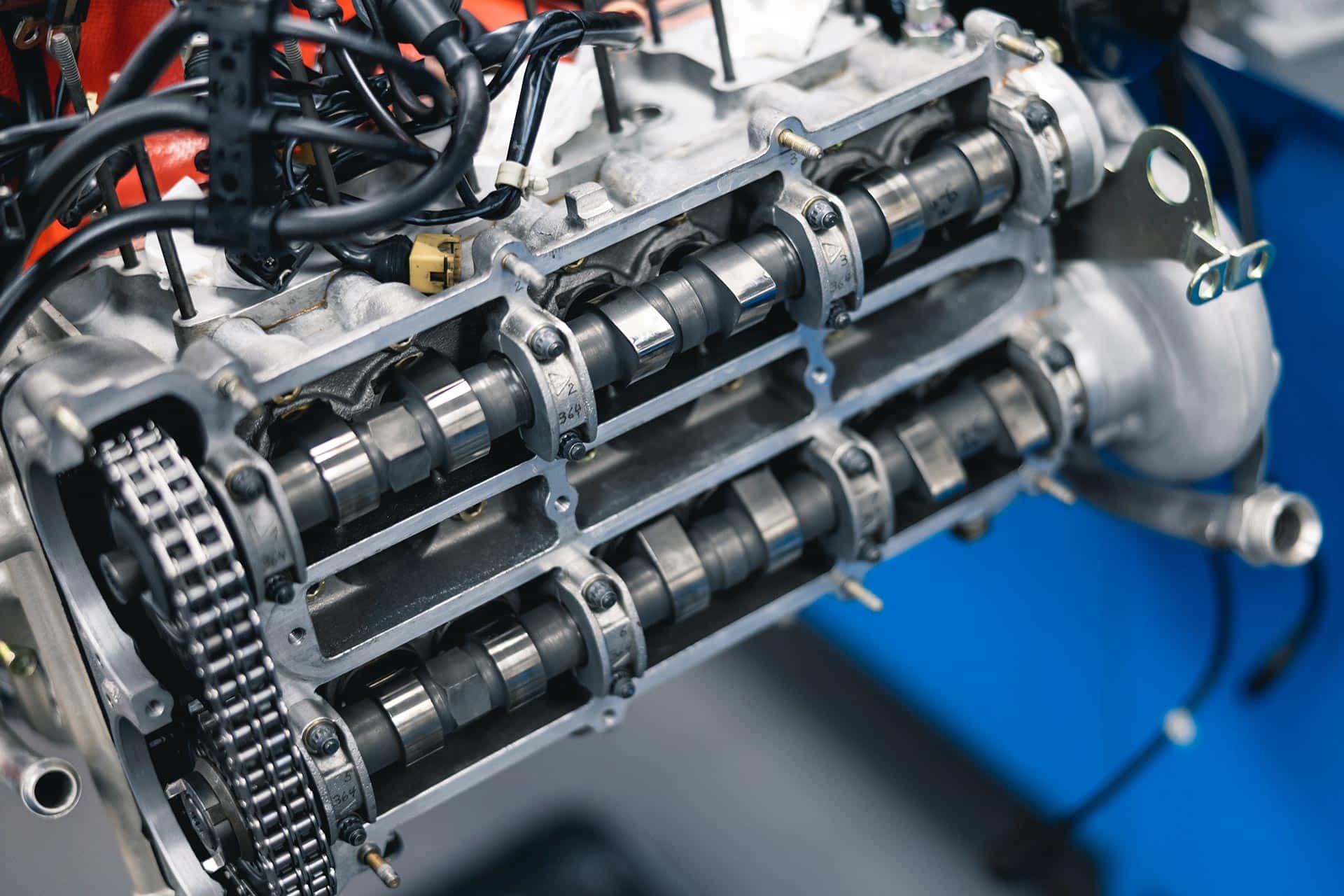

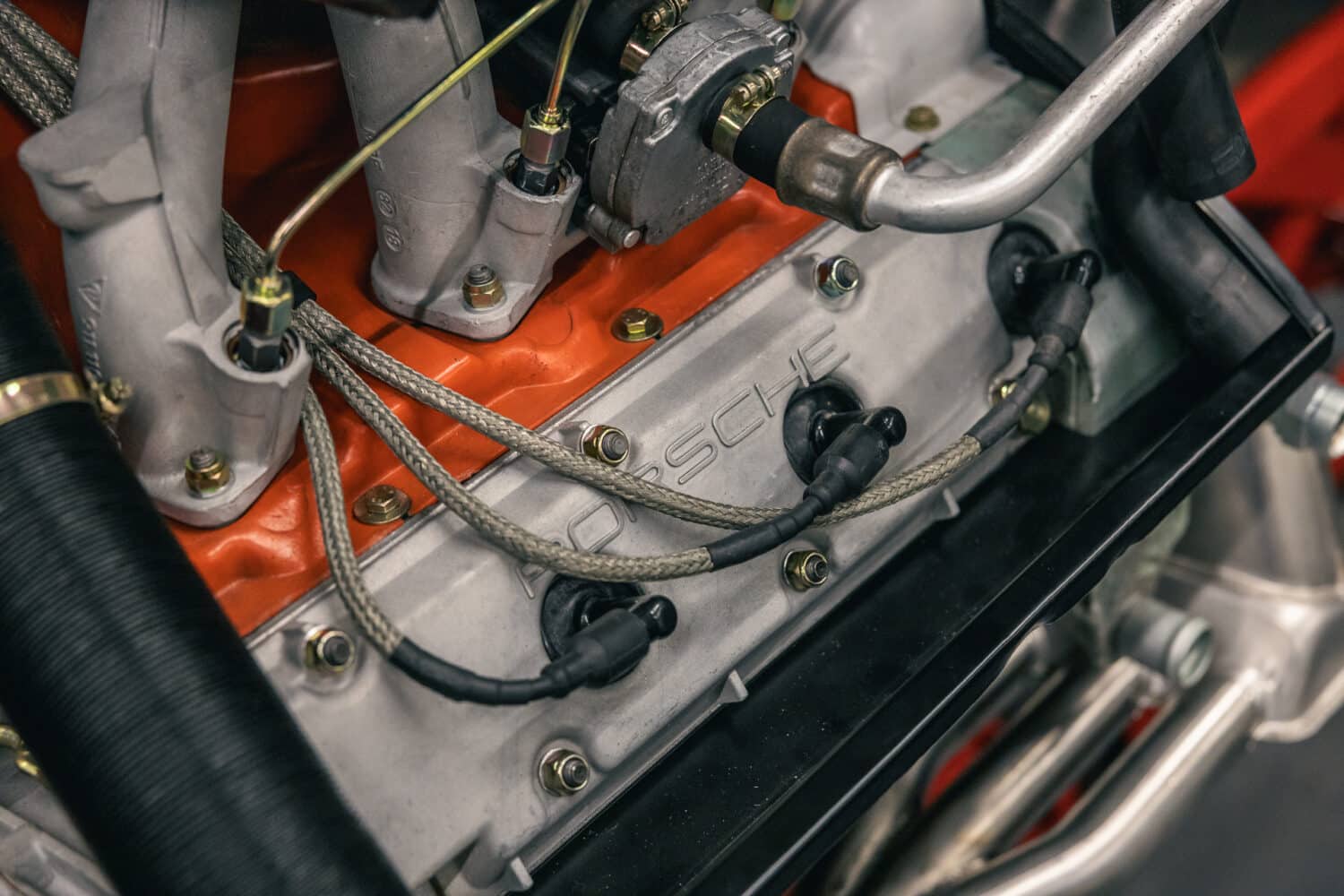

The air-cooled aspect of the engine is as simple as it sounds! An air-cooled engine works by using air to directly cool the engine, rather than the more widely used method of using air to cool a water-based coolant that in turn cools the engine. If we took a 964 engine from the 911 produced between 1989 and 1994, we can see that the crankcases are at the centre of the engine, so-called as this is where the crankshaft is housed. The crankshaft is rotated by the sequential firing of pistons. The pistons are attached to the crankshaft by conrods and run inside cylinder barrels, which in turn are all held in place by the cylinder heads. All of which are secured by long crankcase “head” studs. We can see the barrels and cylinder heads have ‘fins’ on them to allow heat to be dispersed much more quickly than if it were a solid piece of metal (the same principle as a radiator).

The engine’s lifeblood is the oil circulating within it, which lubricates the engine internals and also helps cooling. The oil in an air-cooled engine is pumped around the engine and then goes out to the oil cooler located in the front wing area, directly into the airflow at the front of the car, and then back into the engine once it has cooled. There are additional electric fans to aid cooling when the car is not moving. The alternative to an air-cooled engine is a water-cooled engine, this means that the engine temperature is controlled via ‘coolant’ that is pumped around a jacket of the engine to help keep to normal operating temperatures. Water-cooled engines require more parts such as a whole cooling system, water pump and radiators, therefore, adding complexity and weight. So, in the 1930s when Porsche was looking for an engine solution, the idea of fewer parts, with less complexity and therefore less cost, would have appealed greatly.

The air-cooled engine was not only great for road car applications for Porsche but also proved itself to be extremely reliable in endurance race environments. Changes to legislation and the pursuit of an ever-increasing level of performance and refinement dictated a move to water-cooled engines in the late 1990s.

SPEAK WITH OUR AIR-COOLED EXPERTS

If you would like to discuss your air-cooled engine, then please speak to one of our expert team today on +44 (0)1296 663 824.